Motors

Electrical

motors convert electrical energy into mechanical energy, either rotationally or

linearly. Electric current flows through

a conductor in a magnetic field to produce a force that generates motion

(Lorentz Force).

·

The

basic components of a motor include:

o

Stator: Stationary part that produces a

magnetic field using magnets or coils

o

Rotor: Rotating part that is driven by the

stator’s magnetic field

o

Windings: Coils of insulated wire wrapped around

the stator core or rotor to create magnetic fields when electricity flows

through them

o

Shaft: Rod that passes through the motor and

transmits rotational force to a load

o

Power

Source: Supplies

electrical energy to the motor

·

Types

of Electric Motors

o

Direct

Current “DC” Motors: Powered by DC

supply, often found in robotics and electronics

o

Alternating

Current “AC” Motors: Powered by AC

mains, often found in household and industrial applications

o

Stepper

Motors: Rotates in precise steps, used in robotics and CNC

o

Servo

Motors: Rotates with precise position

control, used in automation and robotics

o

Linear

Actuator: Converts rotation to linear motion, used in robotics and standing

desks

Motor

Driving Concepts

·

H-Bridge:

Uses Boolean signals to control the direction that the motor

spins (clockwise vs. counterclockwise)

o

The

Boolean signal defines the motor’s polarity by changing the direction that the

current flows through a motor

o Switching the polarity switches between

a clockwise and counterclockwise motor rotation

|

Clockwise |

Counterclockwise |

|

|

|

·

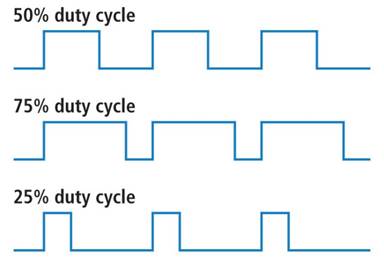

Pulse

Width Modulation (PWM):

Commands a percentage to define how much of a motor’s total available ‘effort’

(Duty Cycle) to output as a digital signal

o

The

power delivered to the motor is not actually reduced to a percentage of the

total motor spec

o

Instead,

the power supplied continually flips between a ‘low’ and ‘high’ state to

simulate a variable voltage that’s bound between the min and max operating

speed

§

This

state flipping is not perceivable to the human eye

·

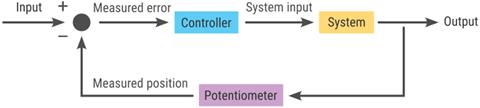

Motor

Control

o

Motors

can be driven more precisely when a control system is implemented. The selected control system depends on the

motor’s application, but common control systems can include Proportional,

Integral, Derivative (PID) controllers and Bang-Bang (hysteresis)

controllers. These control systems

require a measurement instrument to collect performance feedback that drives

the system controller. A popular

measurement instrument on motors is the tachometer, which measures the motor’s

rotational speed.

o

These

control systems will generally follow the closed loop detailed below:

·

Desired

motor performance is defined (speed, position, etc.) as a ‘steady-state’ value

·

Initial

signal is sent to the motor as a voltage

·

Motor

rotates given a voltage

·

Measurement

instrument on the motor characterizes the motor’s performance in that moment

·

Measured

value returns to the controller as ‘feedback’

·

Controller

compares the feedback value from the current iteration to the defined

‘steady-state’ value to calculate an error and adjusts the signal sent to the

motor

o

Ideally,

this new signal improves the motor’s performance and reduces the error to

arrive at the desired ‘steady-state’ value

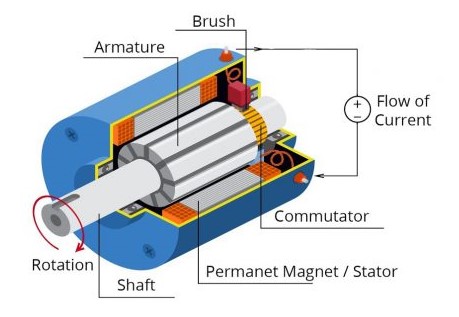

DC Motors

Labeled Brushed DC Motor

Source: powerelectronictips.com

o

DC

Motor-specific Components:

o

Commutator:

Segmented ring that reverses the direction of current in the armature coils and

maintains continuous rotation

o

Armature:

Rotating part of a DC motor (core, windings, commutator)

o

Brushed

vs. Brushless:

o

Brushed

o

Brushless

·

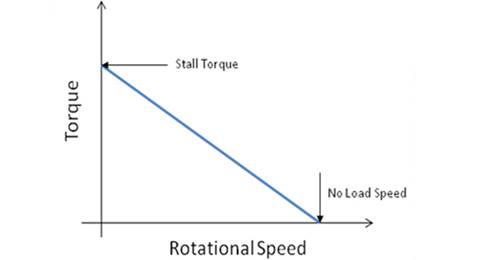

Voltage

à Speed

·

Current

à Torque

·

Gear

Ratio: Motor shaft

turns 48 times for every 1 turn of the output shaft (wheel)

·

Stall

Torque: Maximum

rotational force a motor can produce when the shaft is prevented from turning,

resulting in zero rotational speed

o

When

a motor is at stall torque, it draws maximum current which can lead to

overhearing and damage if stalled for too long

o

Stall

current can be measured by connecting an ammeter in series with the motor,

physically fixing the motor shaft to prevent it from turning, and applying

voltage to the motor. The ammeter

reading when the motor is physically stalled is the stall current.

·

Constant

Voltage: Torque is inversely proportional to Rotational Speed

o

Stall

torque occurs when

rotational speed = 0, so where the torque-speed curve intersects the y-axis

o

Zero-torque occurs when rotational speed = maximum,

also known as the no-load speed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

·

Determine

the motor’s torque and a given speed using the equation of a line to define the

torque-speed curve

|

|

|

|

|

|

|

|

|

|

|

|

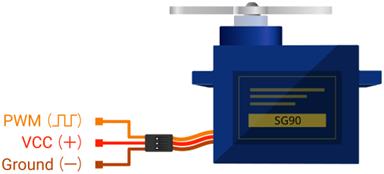

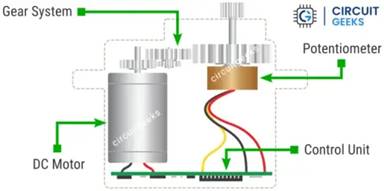

Servo Motors

Source: Circuit Geeks

·

Position-controlled

motor that can be useful to precisely control the position of robotics

·

Rotation

range: ![]()

o

No

continuous motor movement

·

Disadvantages:

o

Slower

movements

o

Lower

output power than other motor types

Source: Circuit Geeks

·

Components:

o

DC

Motor

o

Gearbox:

Reduce speed and increase torque; drives position of the output shaft, measured

in degrees

o

Potentiometer:

Monitor the position of the output shaft and deliver position feedback

o

Control

Circuit: Interprets the input signal to determine the position of the arm and

how much movement is required

Source: Circuit Geeks

·

Consists

of 3 wires (wire colors may vary by motor):

o

VCC

(5V): Supplies electric current to motor

§

Know

how much power the use-case requires to know how much power / current it will

need to pull from its power source

·

Different

motors and use-cases will have different requirements depending on the size and

workload

§

Power

supply rating should be greater than the stall current of the servo, per servo

connected to the power supply

·

![]()

·

Consider

the PCA9685 for controlling multiple servo motors with one

microcontroller

o

GND

o

Signal

(PWM): Delivers control signal to motor (degrees, ![]() )

)

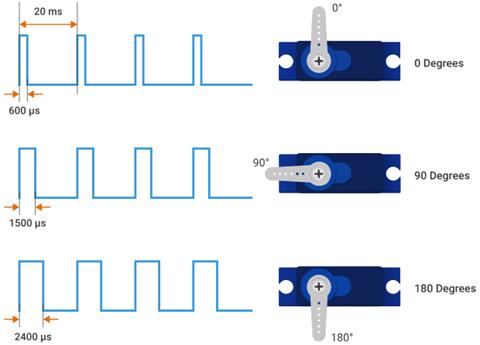

·

Servo

motors are driven by indicating the angle at which the output shaft should be

positioned, expressed in degrees

o

Signal

delivered as PWM

§

Pulse

width determines servo arm position

Source: Circuit Geeks

Helpful

Links