Unmanned

Ground Vehicle (UGV)

This project

was inspired by a curiosity for a very popular technology: Simultaneous

Localization and Mapping (SLAM). From automated

robotic home vacuum systems to show ride vehicles at world-class theme parks,

this technology cleverly intersects mechanics, electronics, and software to

automate a platform’s journey through space.

I’m drawn to this project because it challenges me to approach a design

from the perspective of multiple engineering disciplines and work toward one

technical goal: SLAM.

Tech Stack

|

Mechanical |

Electronics |

Software |

Development

Environment |

|

Fusion 360 |

Raspberry Pi

4 Model B |

Python

3.11.2 |

Visual Studio

(VS) Code |

|

Boss

Laser LS-1630 |

L298N Motor

Driver |

Lightburn |

VS Code

Remote-SSH Extension |

|

Bambu Lab A1

3D Printer |

ESP32

UWB Pro with DW1000 |

Bambu

Studio |

Windows Subsystem

for Linux (WSL) |

|

DC

Motors |

MaUWB STM32 AOA |

|

Linux:

Debian |

|

SG90

Servo Motors |

|

|

GitHub |

Budget

|

Item |

Vendor |

Unit Price |

Qty. |

Units |

TOTAL |

Details |

Notes |

|

Acrylic Sheet 10" H x 8"

W x 0.11" D |

Hobby Lobby |

$3.99 |

4 |

count |

$15.96 |

Platform Panels, Peripheral

Mounting Plates, manufactured with laser cutting |

MFD FX Maker Space |

|

#10-24 x 2-1/2" SS Pan

Philips Machine Screw |

Ace Hardware |

$1.00 |

4 |

count |

$4.00 |

Platform Panel Standoffs |

|

|

#10/24 Nylon Cap (Acorn) Nut |

Ace Hardware |

$1.09 |

4 |

count |

$4.36 |

Platform Panel Standoffs |

|

|

5/16" X 2" Tension Pin

300 Series |

Ace Hardware |

$1.69 |

4 |

count |

$6.76 |

Platform Panel Standoffs |

|

|

Breadboards and Jumpers Kit |

Amazon |

$9.99 |

1 |

count |

$9.99 |

Peripheral Wiring |

|

|

L298N Motor Driver, 2 DC TT

Motors/Wheels |

Amazon |

$7.99 |

1 |

Count |

$7.99 |

Motor and Wheel Assemblies, Motor

Driver Combo Kit |

|

|

3D Print Drive Motor and RasPi Mounts |

OCLS Melrose Ctr. |

$0.05 |

30 |

grams |

$1.50 |

Drive Motors and Raspberry Pi

Mounts |

MFD OCLS Melrose Ctr. |

|

#10-24 x 1/2" Screw |

Ace Hardware |

$0.60 |

8 |

count |

$4.80 |

Fasten RasPi

Block and Motor Mount Blocks to Platform |

|

|

#10-24 Nylon Hex Nut |

Ace Hardware |

$0.45 |

8 |

count |

$3.60 |

Fasten RasPi

Block and Motor Mount Blocks to Platform |

|

|

M3 x 30mm Screw |

Ace Hardware |

$0.60 |

4 |

count |

$2.40 |

Fasten Motor to Motor Mount Block |

|

|

M3 Washer |

Ace Hardware |

$0.55 |

4 |

count |

$2.20 |

M3 Screw to Motor Mount Block

(between screw head and motor mount outer face) |

|

|

M3 Hex Nut |

Ace Hardware |

$0.45 |

8 |

count |

$3.60 |

Fasten Motor to Motor Mount Block

(one on either side of motor, per fastener) |

|

|

#10-24 x 3/8" SS Pan Philips

Machine Screw |

Ace Hardware |

$0.40 |

2 |

count |

$0.80 |

Fasten Caster Mount to Platform |

|

|

#10-24 Nylon Hex Nut |

Ace Hardware |

$0.45 |

2 |

count |

$0.90 |

Fasten Caster Mount to Platform |

|

|

#10-24 x 1/2" Screw |

Ace Hardware |

$0.60 |

2 |

count |

$1.20 |

Fasten L298N Motor Driver Mount to

Platform |

|

|

#10-24 Nylon Hex Nut |

Ace Hardware |

$0.45 |

2 |

count |

$0.90 |

Fasten L298N Motor Driver Mount to

Platform |

|

|

M3 x 10mm Standoff |

Amazon |

4 |

count |

Fasten L298N Motor Driver to Mount |

|||

|

M3 x 6mm Screw |

Amazon |

4 |

count |

Fasten L298N Motor Driver to Mount |

|||

|

M3 Hex Nut |

Amazon |

4 |

count |

Fasten L298N Motor Driver to Mount |

|||

|

Self

Adhesive Caster Wheel |

Amazon |

$0.75 |

1 |

count |

$0.75 |

Purchased in a pack of 8 for $5.99 |

|

|

ESP32 UWB Pro with Display with

DW1000 |

Makerfabs |

$54.80 |

2 |

count |

$109.60 |

Localization module – need 4

modules total for trilateration (1 tag, 3 anchors) |

|

|

3D Print SG90 Servo Motor Mount |

OCLS Melrose Ctr. |

$0.05 |

2 |

grams |

$0.10 |

SG90 Servo Motor Mount |

MFD OCLS Melrose Ctr. |

|

#10-24 x 3/8" SS Pan Philips

Machine Screw |

Ace Hardware |

$0.40 |

2 |

count |

$0.80 |

Fasten SG90 Servo Motor Mount to

Platform |

|

|

#10-24 Nylon Hex Nut |

Ace Hardware |

$0.45 |

2 |

count |

$0.90 |

Fasten SG90 Servo Motor Mount to

Platform |

|

|

M2 x 5 + 3mm Standoff |

Amazon |

|

2 |

count |

|

Fasten SG90 Servo Motor to Mount |

|

|

M2 x 3mm Screw |

Amazon |

|

2 |

count |

|

Fasten SG90 Servo Motor to Mount |

|

|

M2 Hex Nut |

Amazon |

|

2 |

count |

|

Fasten SG90 Servo Motor to Mount |

|

|

#10-24 x 3/8" SS Pan Philips

Machine Screw |

Ace Hardware |

$0.40 |

2 |

count |

$0.80 |

Fasten Breadboard Mount to

Platform |

|

|

#10-24 Nylon Hex Nut |

Ace Hardware |

$0.45 |

2 |

count |

$0.90 |

Fasten Breadboard Mount to

Platform |

|

|

3D Print 6V Battery Mount |

OCLS Melrose Ctr. |

$0.05 |

19 |

grams |

$0.95 |

6V Battery Mount |

MFD OCLS Melrose Ctr. |

|

#10-24 x 3/8" SS Pan Philips

Machine Screw |

Ace Hardware |

$0.40 |

2 |

count |

$0.80 |

Fasten Battery Mount to Platform |

|

|

#10-24 Nylon Hex Nut |

Ace Hardware |

$0.45 |

2 |

count |

$0.90 |

Fasten Battery Mount to Platform |

|

|

2/4/6/8 x 1.5V AA Battery Holder |

Amazon |

$8.90 |

1 |

count |

$8.90 |

|

|

|

Crimp Pin Connector Kit (Pins,

Housings) |

Amazon |

$9.99 |

1 |

count |

$9.99 |

Miscellaneous wire work |

|

|

Polyolefin Heat Shrink Tube 1/8”

(3.2mm) |

Ace Hardware |

$3.59 |

1 |

count |

$3.59 |

Pack of 7; Miscellaneous wire work |

|

|

M2.5 x 10 + 6mm Standoff |

Amazon |

|

4 |

count |

|

Per module – 4 Modules in

Assembly: 1 Tag, 3 Anchors |

|

|

M2.5 x 15 + 6mm Standoff |

Amazon |

|

4 |

count |

|

Per module – 4 Modules in

Assembly: 1 Tag, 3 Anchors |

|

|

M2.5 x 6mm Screw |

Amazon |

|

8 |

count |

|

Per module – 4 Modules in

Assembly: 1 Tag, 3 Anchors |

|

|

M2.5 Hex Nut |

Amazon |

|

8 |

count |

|

Per module – 4 Modules in

Assembly: 1 Tag, 3 Anchors |

Technical

Drawings

Mobile Platform Base

|

|

|

·

The

platform bases are designed like a pegboard to make the UGV more modular, and

they’re manufactured from acrylic using a laser cutter

o

This

design facilitates designing and fastening peripheral mounts/attachments and

flexibly position them as needed

o

The

platform bases are manufactured from acrylic for the material’s low

conductivity and ability to withstand heat, thereby reducing unintended

influence on electronic components

o

Laser

cutting the design onto an acrylic sheet allowed for consistent and accurate

cuts

· Laser Cut at

Maker FX Maker Space on Boss Laser LS-1630

Raspberry Pi 4 Model B Mounting Block

|

|

|

·

3D

Printed at Orange County Library – Melrose Center Maker Space on Bambu Lab A1

printer

Breadboard Mounting Plate

|

|

|

·

Breadboard

dimensions: 3.25” X 2.125”

·

Breadboard

comes with adhesive sheet to adhere to mounting plate

· Laser Cut at

Maker FX Maker Space on Boss Laser LS-1630

6V Battery Mounting Block

|

|

|

·

Rev

A:

o

Fastener

head clearance too tight

o

It

is difficult to remove battery box from mounting block without flipping upside

down

§

Needs

space to fully grip battery box for removal from mounting block

·

3D

Printed at Orange County Library – Melrose Center Maker Space on Bambu Lab A1

printer

DC ‘TT’ Motor

|

|

|

·

DC ‘TT’

Motor assembly file from GrabCAD, as indicated in

drawing notes

·

Technical

drawing by me

DC ‘TT’ Motor Mounting Block

|

|

|

· Only the right drive motor mount was

modeled, so the model was mirrored in the Bambu Studio slicing software when 3D

printed to produce the left drive motor mount

·

3D

Printed at Orange County Library – Melrose Center Maker Space on Bambu Lab A1

printer

L298N Mounting Plate

|

|

|

· Laser Cut at

Maker FX Maker Space on Boss Laser LS-1630

SG90 Servo Motor Mounting Block

|

|

|

|

|

|

|

|

|

·

Rev

A

o

The

mounting block is designed to fasten to the servo motor via two M2.5x5+6mm

standoffs, so the print will be 5mm too short for a motor to sit directly in

the saddle without standoffs

o

3D

Printed at Orange County Library – Melrose Center Maker Space on Bambu Lab A1

printer

·

Rev

B

o

Added

missing width dimension in drawing

o

Taller

standoff supports clearing fastener heads and motor wires’ bend radius

o

Narrower

standoff supports improving servo fit in mount saddle

o

Standoff

support thread holes’ diameter increased from 2.1mm to 2.2mm

o

Use

M2x5+3mm standoffs to fasten servo motor to mount

o

3D

Printed at Orange County Library – Melrose Center Maker Space on Bambu Lab A1

printer

·

Rev

C

o

Corrected

over-toleranced dimensions from Rev B

o

New

design allows SG90 servo motor to sit in the mount saddle slot

o

SG90

servo motor fastens to the mount with M2 screws and nuts

o

Replaced

fastener holes with thru holes to allow M2 fasteners to clear the holes and

fasten with the nut

o

Internal

edges rounded to reduce stress points when bearing load

o

3D

Printed on Bambu P1S printer

ESP32 UWB DW1000 Housing

|

|

|

· Made of clear

acrylic so that pin labels and LCD (if present) are visible

· 2 housing

plates per module:

o

Top (side with LCD, if present)

§ M2.5 x 10mm

standoffs

o

Bottom (side with pinout labels), OPTIONAL

§ M2.5 x 15mm

standoffs

· Laser Cut at

Maker FX Maker Space on Boss Laser LS-1630

Pictures of Manufactured and Assembled

UGV

|

|

|

|

|

|

Mechanical

·

More

technical information about motors can be found in my Motors

Tech Notebook.

·

Code

for driving motors with Python on the Raspberry Pi can be found in my github:

o Raspberry

Pi Motor Hat Driver

DC Gear Box Motor – DC ‘TT’ Motor

Technical Specifications

|

DC Voltage |

3V |

4.5V |

6V |

|

Current |

150mA |

155mA |

160mA |

|

Gear Ratio |

1:48 |

1:48 |

1:48 |

|

Minimum Operating Speed |

90RPM +/- 10% |

- |

200RPM +/- 10% |

|

Stall Torque |

0.4kg-cm |

- |

0.8kg.cm |

SG90 Micro Servo Motor

Technical Specifications

|

DC Voltage |

4.8V |

6V |

|

Current |

155mA |

160mA |

|

Approximate Operating Speed |

0.09 - 0.15 seconds per 60 degrees |

0.09 - 0.15 seconds per 60 degrees |

|

Stall Torque |

1.3kg.cm |

1.5kg.cm |

|

Operating Angle |

180 |

180 |

Electrical /

Electronics

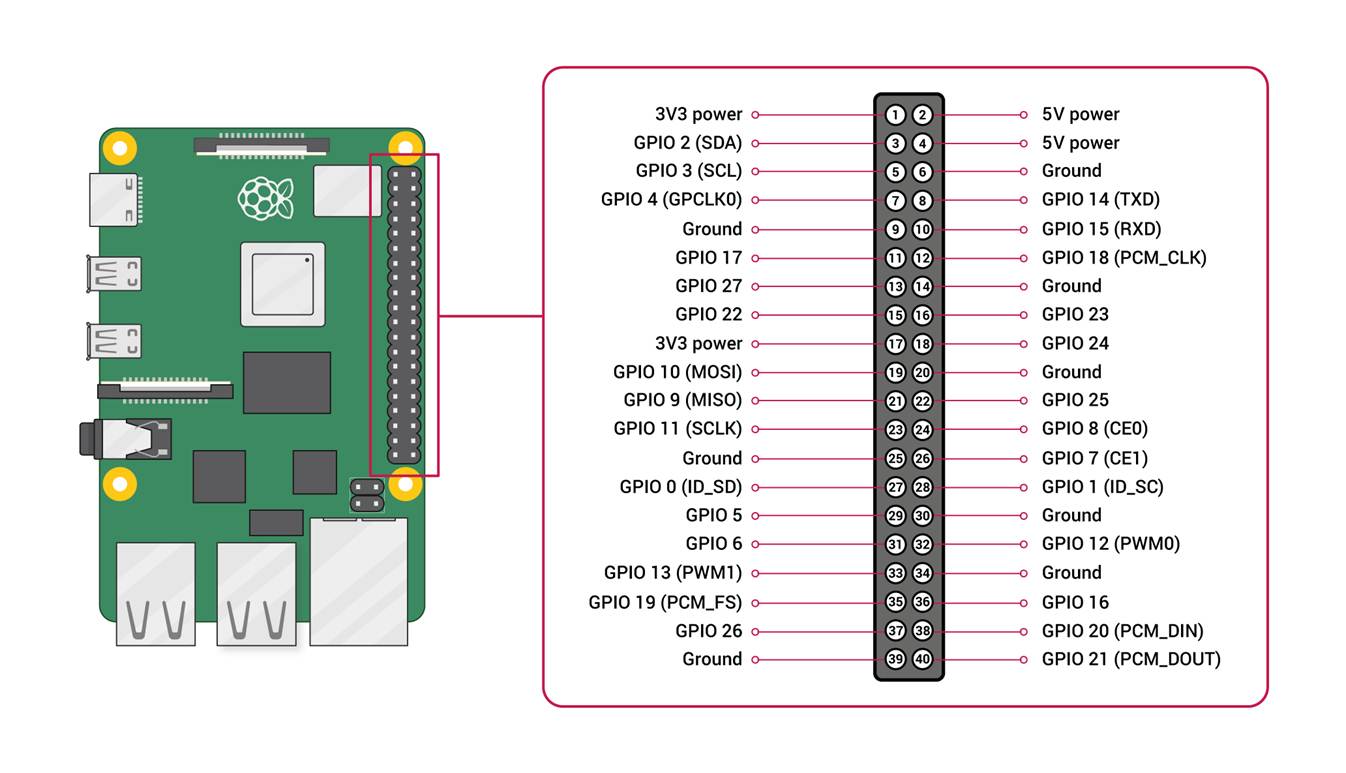

Raspberry Pi 4 Model B

|

Pin Number |

Pin Description |

Pin Assignment |

Pin Number |

Pin Description |

Pin Assignment |

|

1 |

3V3 POWER |

2 |

5V POWER |

L298N POWER IN 5V |

|

|

3 |

GPIO 2 (SDA) |

4 |

5V POWER |

Object Detection Servo 5V |

|

|

5 |

GPIO 3 (SCL) |

6 |

GND |

L298N GND |

|

|

7 |

GPIO 4 (GPCLK0) |

8 |

GPIO 14 (TXD) |

ESP32 UWB DW1000 RXD |

|

|

9 |

GND |

10 |

GPIO 15 (RXD) |

ESP32 UWB DW1000 TXD |

|

|

11 |

GPIO 17 |

L298N MOTOR B IN1 (RIGHT) |

12 |

GPIO 18 (PCM_CLK) |

|

|

13 |

GPIO 27 |

L298N MOTOR B IN2 (RIGHT) |

14 |

GND |

|

|

15 |

GPIO 22 |

L298N MOTOR B EN (RIGHT) |

16 |

GPIO 23 |

L298N MOTOR A IN1 (LEFT) |

|

17 |

3V3 POWER |

ESP32 UWB DW1000 |

18 |

GPIO 24 |

L298N MOTOR A IN2 (LEFT) |

|

19 |

GPIO 10 (MOSI) |

|

20 |

GND |

ESP32 UWB DW1000 |

|

21 |

GPIO 9 (MISO) |

|

22 |

GPIO 25 |

L298N MOTOR A EN (LEFT) |

|

23 |

GPIO 11 (SCLK) |

|

24 |

GPIO 8 (CE0) |

|

|

25 |

GND |

26 |

GPIO 7 (CE1) |

||

|

27 |

GPIO 0 (ID_SD) |

28 |

GPIO 1 (ID_SC) |

||

|

29 |

GPIO 5 |

30 |

GND |

||

|

31 |

GPIO 6 |

32 |

GPIO 12 (PWM0) |

Object Detection Servo Signal |

|

|

33 |

GPIO 13 (PWM1) |

34 |

GND |

Object Detection Servo GND |

|

|

35 |

GPIO 19 (PCM_FS) |

36 |

GPIO 16 |

||

|

37 |

GPIO 26 |

38 |

GPIO 20 (PCM_DIN) |

||

|

39 |

GND |

40 |

GPIO 21 (PCM_DOUT) |

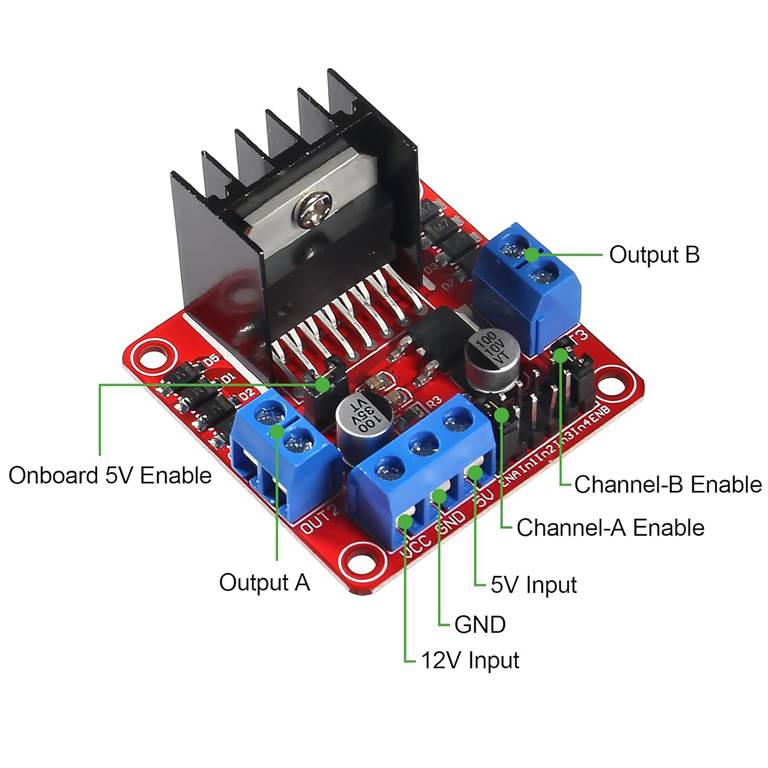

L298N Motor Driver

·

The

DC motors are rated for a voltage that exceeds what a microcontroller outputs

·

A

motor driver provides the motors with an external power source that meets the motor’s

specifications but receives logic signals from the

connected microcontroller

·

The

L298N microcontroller has H-bridge and Pulse Width Modulation (PWM) capability,

controlling the motor’s output effort (i.e. rotation speed) and direction

|

Pin

Label |

Pin

Description |

Pin

Notes |

|

Output

A |

DC

Motor A |

DC

Motor Leads |

|

Output B |

DC Motor B |

DC

Motor Leads |

|

12V Input |

Motor Power Source (+) up to 12V input |

|

|

GND |

Motor Power Source (-) / Microcontroller

Ground |

|

|

5V Input |

5V from Microcontroller Pin for Driver

Logic |

|

|

Channel-A Enable |

PWM: DC Motor A |

1

pin on channel for duty cycle % (float between 0 and 1) |

|

Channel-A IN1/IN2 |

H-Bridge: DC Motor A |

2

pins on channel for Boolean signals (CW: T/F, CCW: F/T) |

|

Channel-B Enable |

PWM: DC Motor B |

1

pin on channel for duty cycle % (float between 0 and 1) |

|

Channel-B IN1/IN2 |

H-Bridge: DC Motor B |

2

pins on channel for Boolean signals (CW: T/F, CCW: F/T) |

·

The

diagram below shows how the L298N motor driver is connected to the DC motors

and the microcontroller logic pins

·

Code

for driving motors on the L298N motor driver with Python on the Raspberry Pi

can be found in my github:

Ultra Wideband (UWB)

·

Ultra-Wideband

(UWB) is a high-precision, short-range wireless radio technology used for

accurate, low-power device localization at short distances

o

Devices

send multiple short radio pulses over a wide frequency band and measure the

time it takes for signals to travel between one another (Time of Flight, ToF) to determine their distance and position

o

Large

bandwidth provides high data rates and stability to reduce interference while

enabling precise positioning

§

Ideal

for indoor positioning and navigation

|

Peripheral |

Proposed Purpose |

|

ESP32 UWB Pro DW1000 |

Localization |

|

MaUWB STM32 AOA |

Docking |

· These modules can communicate with the

microcontroller using Universal Asynchronous Receiver/Transmitter (UART)

protocol, an asynchronous serial communication for short-distance

wired communication

o See

Communication Protocols: UART in Tech Notebook

ESP32 UWB Pro with DW1000

|

CPU |

ESP32 - WROVER |

|

UWB |

DW1000 |

|

Measuring Distance |

200M |

|

UWB Channel |

2/5 |

|

Board USB Supply Voltage Range |

4.8~5.5V, 5.0V Typical |

|

Other Features |

WiFi, BlueTooth |

The ESP32 documentation

defines the pinout for the chip that’s soldered on Makerfab’s

board. The board pins map to the ESP32

chip pins with the corresponding name, as defined in the documentation.

|

ESP32-WROVER Pin Layout Source: Makerfabs

ESP32 UWB with DW1000 Documentation |

ESP32-WROVER Pin Definitions Source: Makerfabs

ESP32 UWB with DW1000 Documentation |

ESP32 UWB Pro Makerfabs

Board Source: Makerfabs

ESP32 UWB Pro with Display |

|

|

|

|

Algorithms

·

All

algorithms implemented in this UGV are documented in the Tech Notes

section of my digital notebook!

o Localization: Trilateration

o Path Planning: A*

Path Planning

Software

·

All

code implemented in this UGV is publicly available on my github!

o Raspberry

Pi Motor Hat Driver

Helpful

Links

·

Makerfabs ESP32 UWB with DW1000