VendArt at MakerFX

This effort aims to restore a National

Vendors, Inc. Manual Cigarette Merchandiser Series 222, which was a classic

mechanical cigarette vending machine that was popular between the 1960s and

1980s. The machine that I’m helping

restore is from 1975, as indicated by a stamp on the vending machine’s internal

hardware.

Date stamp found inside the merchandiser

Another MakerFX

member owns this project, but I’m supporting the effort by restoring the

mechanical vending mechanisms and integrating modern payment solutions while

preserving the machine’s original and existing hardware. When completed, this vending machine will

sell local makers’ unique makes at various Central Florida maker events, like Maker Faire Orlando.

The machine’s vending mechanisms are

locked when idle, preventing the pull knobs from dispensing items from their

respective magazines. When payment is

accepted, a solenoid engages the vending mechanisms to unlock the pull knobs

and enable vending. I was tasked with

replacing the missing solenoid, designing and implementing a solenoid driver,

and writing the code that drives the solenoid during a transaction.

Tech Stack

|

Mechanical |

Electronics |

Software |

Development

Environment |

|

Fusion 360 |

Raspberry Pi Pico W

(Development) |

Python

3.13.9 |

Visual Studio (VS)

Code |

|

Bambu Lab P1S 3D

Printer |

Raspberry Pi Zero

2W (Production) |

Bambu

Studio |

Thonny |

|

Solenoid

12V 10mm 5N Push Pull |

MP1584EN

DC-DC Buck Converter |

Square

API Developer |

GitHub |

|

Infrared

Thermometer |

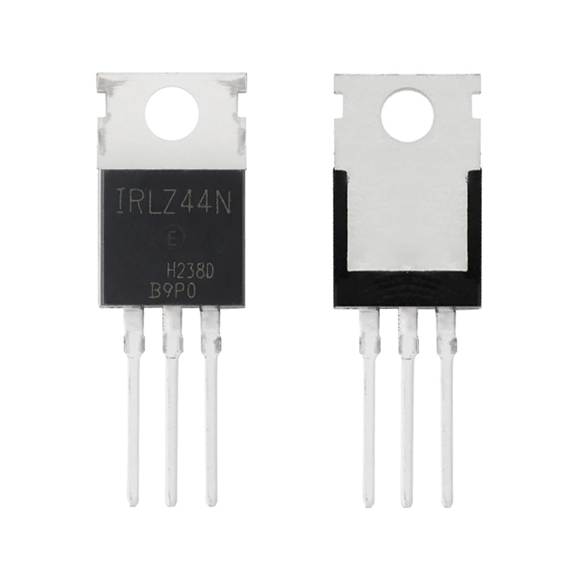

IRLZ44NPBF

Logic Level MOSFET |

ngrok |

|

|

Prototyping |

Breadboard,

Perfboard |

|

|

|

Testbed

and Experiment Design |

Soldering |

|

|

Mechanical

|

|

|

|

|

Left to Right: Internal vending unit front,

merchandise magazines, internal vending unit side, vending lock mechanism

detail

Solenoid 12V 10mm 5A Push Pull

|

|

|

Technical Specifications

|

Voltage |

12VDC |

|

Current |

1.7A |

|

Force |

5N |

|

Stroke |

10mm |

XYZ Adjustable Solenoid Carriage (left)

and Mount (right)

|

|

|

XYZ Adjustable Solenoid Carriage and

Mount Assembly

|

|

·

Carriage

and mount were designed in Fusion 360

·

Carriage

and mount were 3D printed on the Bambu P1S

|

|

|

|

Detail of solenoid on XYZ carriage and mount,

and fastened to existing machine bracket

Retrofitted XYZ Adjustable Solenoid

Carriage and Mount Assembly on Existing Bracket

|

|

|

|

·

The

solenoid carriage and mount are adjustable in the XYZ directions, so the

solenoid can be precisely positioned to engage the vending lock mechanism

o

The

solenoid fastens to the carriage

o

The

carriage fastens to the mount

o

The

mount fastens to the vending machine’s existing bracket

· I designed this XYZ solenoid carriage

and mount assembly to fit the existing bracket

· This design makes it possible to

position the solenoid plunger (piece that extends and retracts) with the

vending machine’s mechanical lock mechanism

· The XYZ carriage and mount positions are

‘locked’ with screws, washers, and nuts creating bolted joints

|

|

Bolted Joint

Solenoid Cycle Temperature Testing

· The solenoid’s plunger extends by

creating a magnetic field when current flows through the tightly wound coils

surrounding the plunger

· Continuous current flowing through the

solenoid coils produces a lot of thermal energy (heat)

o I reduced the solenoid’s input voltage

from 12V to 6V to reduce the heat produced when current is flowing through the

coils

· Since the solenoid is mounted to a

carriage and mount that was 3D printed with PLA, I want to make sure that the

hear produced by the solenoid does not exceed the melting point of PLA

·

I

created a test bed to measure the temperature of the solenoid with an infrared

thermometer

o

I attempted

to keep the ambient temperature constant throughout each experiment run

§

No

AC running, ambient temperature measured during the experiment

o

The

infrared thermometer was mounted onto a tripod to secure its distance from the

solenoid through the experiment

§

The

infrared thermometer’s documentation recommends measuring a temperature from

14”, so I mounted the thermometer at 14” from the solenoid’s top surface where

the temperature was measured

o

The

solenoid was attached to the carriage mount to observe the solenoid’s

temperature effect on the PLA

o

The

carriage mount was securely taped to the test bed to reduce movement between

engages and disengages

·

I

wrote code to iterate through an engage and disengage procedure that parallels

the use-case

o

This

makes the experiment repeatable and the data more accurate

o

Code

available on github

|

|

|

Solenoid Cycle Testbed Setup

·

This

experiment iterated through an engage-disengage cycle for multiple cycles, and

was repeated at various locations on the solenoid

· Procedure

o

Measure

surface temperature at the designated location BEFORE starting engage-disengage

cycles

§

This

location is where the cycle temperatures will be measured for the entire

experiment

o

For

130 cycles

§

Solenoid

engages for 15 seconds

§

Solenoid

disengages and temperature is measured at the designated location

§

Solenoid

remains disengaged for 10 seconds

o

NOTE: DO NOT touch the solenoid or move the

infrared thermometer during the experiment

Locations on solenoid where temperatures

were measured

|

|

Center

Side |

|

|

Center V

Leads Side |

|

|

Center |

|

|

Center

Plunger End |

|

|

Center

Spring End |

· Results

o

Cycles

1-100 cycles: Capture the temperature rise toward a temperature steady-state

o

Cycles

101-130: Measure steady temperature

o

The

results from the experiment agreed with the claim that the solenoid is hottest

near the center of the coil length, as shown in my data below

o

The

experiments’ maximum temperatures had a delta of approximately ![]() , with the center of the coil length

hitting

, with the center of the coil length

hitting ![]() and the end of the coil length hitting

and the end of the coil length hitting ![]()

Solenoid Cycle Temperature Rise and

Steady-State Data

Solenoid Steady-State Temperature Data

|

Location on Solenoid |

Measured Ambient Temperature |

Average Solenoid Steady-State

Temperature |

|

Center Side |

|

|

|

Center V Leads Side |

|

|

|

Center |

|

|

|

Center Plunger End |

|

|

|

Center Spring End |

|

|

· Data Variability

o The Average Solenoid Steady-State

Temperatures had a sample variance of 5.42℃^2,

or a standard deviation of 2.33℃

§ Variance represents the average of the

squared distance from the mean, which conveys the distribution of the data

|

Average |

|

|

|

Sample

Variance |

|

|

|

Standard

Deviation |

|

|

o This data has a low variance, which

means that the data is closer to the average

o Low variance is an indication of

consistent measurements during data acquisition. Conversely, high variance indicates unusual

or inconsistent data

· Conclusion

o The Average Solenoid Steady-State

Temperatures had a sample variance of 5.42℃^2,

or a standard deviation of 2.33℃

o PLA begins to soften at ![]() and melts at

and melts at ![]()

o This cycle test was more aggressive than

the cycles that the fielded solenoid will experience and was still ![]() under the softening temperature

under the softening temperature

o The heat produced from the active solenoid

should not affect the PLA carriage mount

o As an extra experiment, I allowed the

solenoid to cycle through engage and disengage for 200 cycles with no impact to

the solenoid’s performance or the PLA carriage mount

§ No data collected – Just observation for

any impacts to the system at high cycle counts

· How to Improve Future Experiment

o Automate temperature readings with

software instead of manually pressing the thermometer trigger

§ Reduces human error by with more

consistent timing between measurements

§ Eliminates all shaking of the

thermometer when user presses the thermometer trigger

§ Collect more frequent temperature data

throughout the experiment to create a more complete temperature profile of the

solenoid

o Perform experiment in a more controlled

environment

§ Thermal chamber

Electronics

Raspberry Pi Pico W

|

|

|

MP1584EN DC-DC Buck Converter (Step-Down

Converter)

|

|

|

|

·

I

wanted the solenoid and microcontroller to share one 12VDC power source, but

both components have different electrical requirements:

o

Solenoid:

12VDC, 1.7A

o

Raspberry

Pi Pico W: 5V, 95mA

·

A

buck converter, AKA step-down converter, efficiently reduces a higher input DC

voltage to a lower output DC voltage

o

This

protects the lower-voltage components that are connected to a higher DC source

voltage

·

An

inductor stores and releases electromagnetic field and smooths the current by

resisting rapid changes

·

A

switch creates a duty cycle that outputs a desired voltage lower than the

source

o

The

lower the duty cycle, the lower the store in the inductor

o

Think

Pulse Width Modulation (PWM)

o

The

switch is usually a transistor (MOSFET)

·

A

diode creates a path for the current when the switch is turned off

·

A

capacitor smooths the voltage rippled

·

The

buck converter unit uses a control (potentiometer) to control the output

voltage

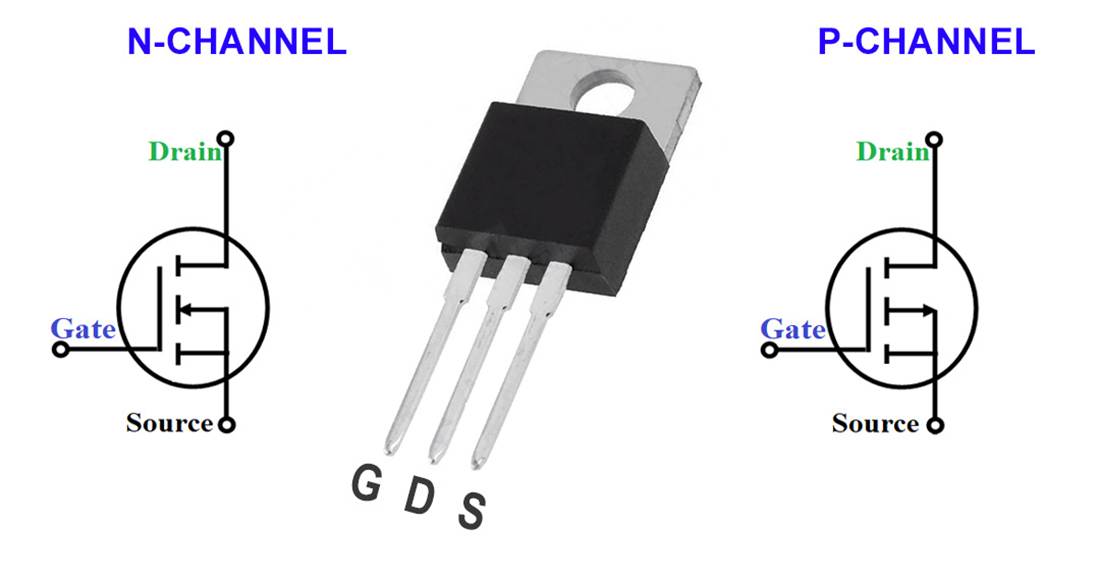

IRLZ44NPBF Logic Level MOSFET

IRLZ44N

Logic-Level MOSFET

·

A

MOSFET is an electronic switch that controls current flowing through a

semiconductor channel using an electric field

o

MOSFET

Terminals

§

Gate

(G): Control Input

§

Drain

(D): Where current flows out

§

Source

(S): Where current flows in

o

N-Channel:

§

Turns

on when the gate is more positive than the source

§

Current

flows from drain to source

§

Efficient

and low heat

§

Motor

drivers, solenoids, power supplies, high-current applications

o

P-Channel

§

Turns

on when the gate is more negative than the source

§

Current

flows from source to drain

§

Simpler

but less efficient at high currents (higher ![]() )

)

§

Battery-powered

devices

·

The

IRLZ44N is a logic-level N-channel MOSFET, which allows us to engage and

disengage the solenoid by passing a boolean to the

MOSFET gate with the solenoid driver code

·

2

main parameters for selecting the appropriate MOSFET: Voltage (V) and Current

(I)

|

|

|

|

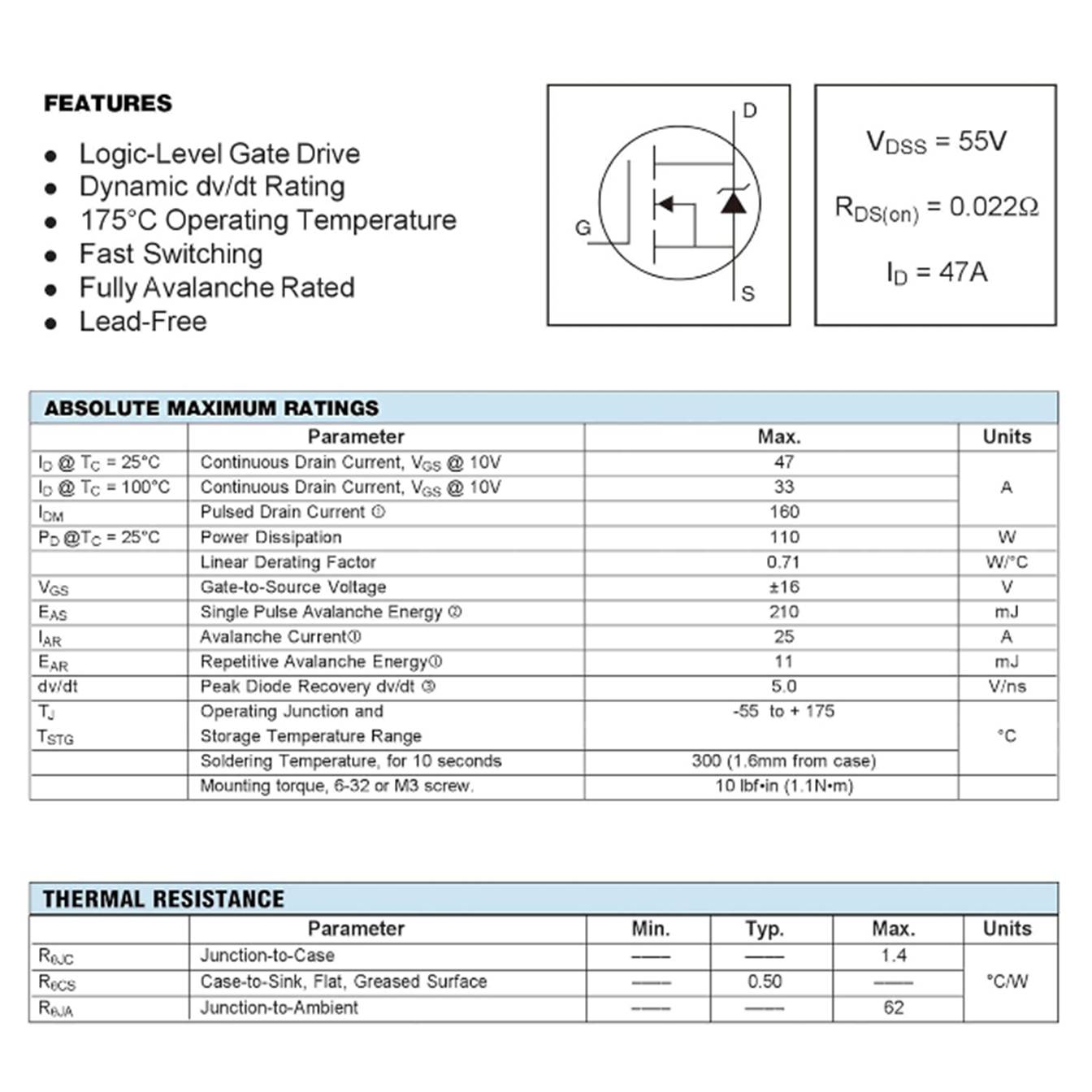

· MOSFET Spec Sheet

o

Spec

sheet assumes proper cooling, so operating the MOSFET at the rated specs

without proper cooling (fans, heat sinks, etc.) can overheat or melt the unit

o

The

Current spec only says that the MOSFET will not melt when operating at 47A when

properly cooled

§

While

the Current and Voltage are used to determine how a system will operate, the

MOSFET’s internal resistance, ![]() , sets the threshold

, sets the threshold

·

![]() tells how much power needs to dissipate from

the MOSFET at a constant load

tells how much power needs to dissipate from

the MOSFET at a constant load

o

Constant

Load: >10 seconds without a heat sink

IRLZ44N

MOSFET Spec Sheet

· Thermal Power Generated

o

Recall

– the internal resistance, ![]() , is the spec that we will use to

threshold our MOSFET selection calculations

, is the spec that we will use to

threshold our MOSFET selection calculations

o

Since

there isn’t perfect control of the load on the MOSFET, we degrade the ![]() by 20-30%

by 20-30%

§

Increase

![]() by 20%:

by 20%:

![]()

|

|

o

Now

calculate the thermal power generated, ![]() , by the system given the load’s specs

, by the system given the load’s specs

§

Since

we are using the MOSFET to drive the solenoid, we are using the solenoid specs

defined above as the load

|

|

|

|

|

|

· Thermal Power Lost

o

These

thermal losses need to somehow escape the MOSFET, and that can be determined

with the thermal resistance, ![]()

§

This

tells you how much the MOSFET will heat up for each watt of thermal loss, ![]()

o

Now

that we’ve solved for ![]() , we can calculate the thermal losses to

confirm that they are within the MOSFET’s specifications

, we can calculate the thermal losses to

confirm that they are within the MOSFET’s specifications

§

The

MOSFET spec sheet indicates that the Thermal Resistance, ![]() , for a MOSFET without a heatsink

(Junction-to-Ambient) is

, for a MOSFET without a heatsink

(Junction-to-Ambient) is ![]()

·

Use

the heatsink spec sheet if a heatsink is screwed onto your MOSFET

·

We

assume that ambient is ![]() when unknown or unspecified

when unknown or unspecified

§

We

calculate the thermal loss by multiplying the thermal power generated, ![]() , and the thermal resistance,

, and the thermal resistance, ![]()

|

|

|

|

|

|

o The calculated thermal loss can be

compared to the Operating Junction ![]() and Storage

and Storage ![]() Temperature

Range indicated on the spec sheet:

Temperature

Range indicated on the spec sheet:

|

|

o Since the calculated temperature from

thermal losses falls within this spec, we determine that the MOSFET can safely

operate under the solenoid’s load

|

|

· MOSFET Drive Levels

o

Since

this MOSFET is a logic-level MOSFET, we need the voltage from the logic signal

that the microcontroller produces

§

The

solenoid will be driven by the Raspberry Pi Pico W microcontroller, which

outputs 3.3V

o

The

MOSFET spec to track here is the Static Drain-to-Source On-Resistance, ![]()

o

Notice

that the resistance values on this spec are more in line with the resistance we

calculated losses with at the 20% margin

§

Resistance

goes up as the voltage goes down, which is the relationship indicated by ![]()

· Confirm MOSFET selection

o

The

spec sheet doesn’t indicate Static Drain-to-Source On-Resistance, ![]() , but I still want to confirm that my

system won’t exceed the MOSFET’s thermal constraints

, but I still want to confirm that my

system won’t exceed the MOSFET’s thermal constraints

o I’m using the indicated ![]() for 5V and 4V to linearly extrapolate

for 5V and 4V to linearly extrapolate ![]() for the microcontroller’s 3.3V

for the microcontroller’s 3.3V

|

|

|

|

|

|

|

|

o Now that ![]() is calculated for my system, I can revisit the

calculations and use my estimated

is calculated for my system, I can revisit the

calculations and use my estimated ![]() to

more accurately determine the thermal effects on the MOSFET

to

more accurately determine the thermal effects on the MOSFET

|

|

|

|

|

|

|

|

|

o At ![]() , I’m still well within the Operating

Junction

, I’m still well within the Operating

Junction ![]() and Storage

and Storage ![]() Temperature

Range indicated on the spec sheet, so my solenoid driver will not thermally

compromise the MOSFET

Temperature

Range indicated on the spec sheet, so my solenoid driver will not thermally

compromise the MOSFET

o

This

MOSFET is excessive for my solenoid driver’s electrical parameters, but its

large voltage and current margin will be reliable and usable

Solenoid Driver Wiring Schematic,

designed in TinkerCAD Electrical

Solenoid Driver Breadboard

|

|

|

|

Breadboard for solenoid driver

development

Soldered Perfboards

|

|

|

Left

to Right (per image): Solenoid, Solenoid Driver, Buck

Converter, Raspberry Pi Pico Microcontroller, Redundancy Engage and Disengage

Buttons

Solenoid

Driver/Buck Converter Stack

|

|

|

Assembled solenoid driver unit on

soldered perfboard

Software

Vending Flow of Execution

· Point of Sale (POS) Solenoid Engage

o

The

trigger that commands the solenoid to engage and unlock the vending lock

mechanism is an initiated transaction

o

Once

initiated, the solenoid will remain engaged until an item is dispensed or the

defined engage time expires

§

Solenoids

engage by running a continuous current, so they get very hot when engaged

§

A

timed disengage is a safety parameter that protects the solenoid from

overheating in its engaged state

o

The

point of sale is performed via digital payment platform (DPP)

§

Square,

Stripe, Venmo, Zelle, etc.

o

When

a transaction is initiated, a webhook is posted to the defined endpoint from

the DPS

o

Receipt

of the webhook then commands the solenoid driver to engage and unlock the

vending lock mechanism

· Webhook Implementation

Production Webhook Implementation,

Raspberry Pi Zero 2W

o

I

decided to use a webhook instead of an API to keep the design efficient

§

API: System (client) pulls data or

an event from another system (host) when the client system sends a request

·

Host:

Data Source

·

Client:

Data Requester/Recipient from an endpoint

§

Webhook: System (client) automatically pushes

data to another system (host) when the client system detects an event

·

Host:

Data Recipient

·

Client:

Data Source that sends a POST to a URL endpoint

o

Instead

of polling the endpoint with an API, a webhook is sent to a server when the

endpoint detects an event

§

The

host (receives the webhook) is ‘listening’ for a POST request from the client

(sends the webhook)

§

The

API for the service I’m using limits the number of calls to the host, but not

webhooks as long as data receipt is confirmed

o

The

server to which the webhook posts is hosted locally on the Raspberry Pi, but

the server needs to be publicly accessible so that the external DPP can post

the webhook

o

A secure

tunnel creates an encrypted pathway for data to travel between two

endpoints over HTTP protocol

o

The

secure tunnel securely exposes the local server on the Raspberry Pi (host) to

the internet, enabling the external DPP (client) to post to it

§

The

Raspberry Pi (host) server ‘listens’ for a webhook post from the external

client

§

When

payment is accepted by the DPP, the DPP (client) sends a webhook to the server

hosted on the Raspberry Pi (host) via a secure tunnel to inform of a received

payment

§

The

local host must send a receipt confirmation to the client when the webhook is

received, typically within approximately10 seconds of receipt

·

Confirmation:

200 code

Dev Implementation

Development Webhook Implementation,

Raspberry Pi Pico W

o

My

dev environment uses a Raspberry Pi Pico W, which is a microcontroller, so it

can’t run a secure tunnel

o

I’m

using my laptop to create a local server and implement a secure tunnel that

receives webhooks from the DPP endpoint

o

The

laptop sends a Boolean to the Raspberry Pi Pico W’s IP on a common network when

a webhook is received, commanding the solenoid driver to engage the solenoid in

the vending lock mechanism

o

The

deliverable will consolidate the Raspberry Pi Pico W and the laptop with a

Raspberry Pi Zero 2W, which can host a local server and implement a secure

tunnel, following the first diagram in this section

·

All

code implemented in this notebook is publicly available on my github!

Helpful

Links

· MOSFET Explained - How MOSFET Works

· MOSFET Selection Calculations